The Era of All-in-One Machining: GPM’s B-axis Sets the Future Standard for Turn-Mill Machining

As the manufacturing landscape evolves toward customization, small-batch production, and fast delivery, traditional segmented workflows are struggling to keep up with modern design complexity and stringent quality demands.

Conventional processes—where turning, milling, and drilling are done on separate machines—require multiple setups and re-alignments. This wastes time and introduces cumulative errors, making it increasingly difficult to achieve “complete machining in a single setup.”

That’s why CNC turn-mill machines, integrating multiple functions and high-performance spindles, have become the new mainstream for precision manufacturing. In this transformation, the choice of a truly capable multi-tasking spindle module is the key to unlocking full productivity.

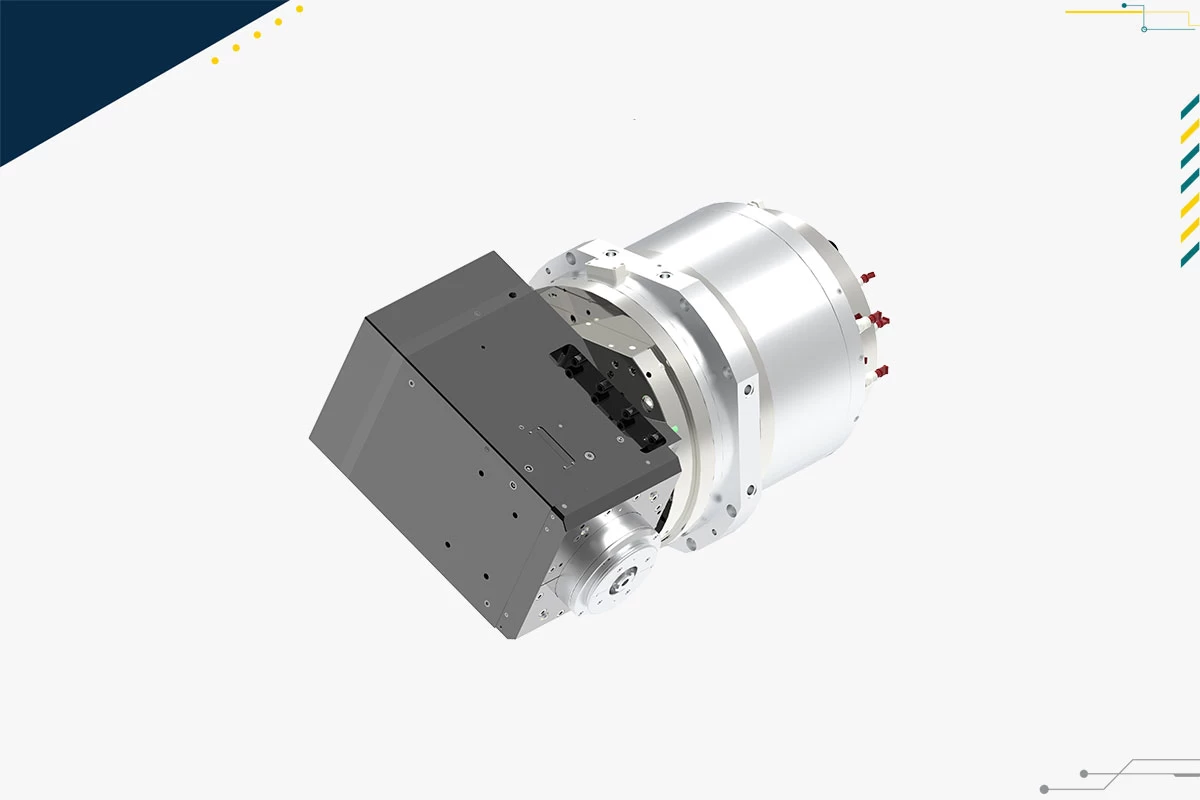

GPM Motor Spindle + B-axis DD Table: The Core of Next-Gen Turn-Mill Integration

To meet the growing global demand for multi-face and multi-angle machining, GPM developed its Motor Spindle + B-axis Direct Drive (DD) Table module, engineered specifically for CNC turn-mill machines. This solution offers unmatched speed, torque, flexibility, and modularity—addressing the real needs of advanced manufacturing.

1. High-Speed, High-Torque Performance for Any Material

GPM’s motor spindle delivers up to 12,000 rpm, supported by an advanced water-cooling system for thermal stability during extended high-speed operation. With torque levels up to 120 Nm, it handles challenging materials such as stainless steel, titanium, and alloy steels, while also enabling high-speed machining of aluminum and composites.

This makes it ideal for industries like aerospace, medical, semiconductor, and mold making, where tool life, dimensional accuracy, and surface finish are critical.

2. B-axis with Direct Drive—True Multi-Face Machining in One Setup

The B-axis offers a ±120° swivel range powered by a Direct Drive motor, ensuring fast, precise, and backlash-free angular control. This enables efficient execution of angled drilling, contour milling, and complex 5-face machining.

Whether you’re producing turbine blades, orthopedic implants, or injection mold bases, the GPM B-axis enables full-part machining in one setup—minimizing manual error, improving precision, and maximizing throughput.

3. Modular, Builder-Friendly Design for Global Integration

Designed for easy integration across global CNC platforms, GPM’s B-axis module supports various tool interfaces including HSK, PSC, and CAPTO, and offers flexible spindle configurations to match diverse machine architectures.

This modular approach allows CNC machine builders and integrators to quickly develop new-generation multi-tasking machines for industries such as automotive, electronics, aerospace, and more—reducing time-to-market and enhancing system versatility.

Proven Worldwide: Performance + Service You Can Count On

GPM’s B-axis solutions are already trusted by CNC machine brands and manufacturers across Japan, Korea, Germany, Italy, Taiwan, and Southeast Asia. Beyond technical superiority, GPM also offers:

- Multilingual Global Support:English- and Japanese-language documentation and remote support.

- Custom Design & Fast Delivery:In-house design and assembly ensure rapid production and flexible customization.

- Collaborative Development:Partnering with machine builders through co-design, OEM/ODM services, and full integration support.

Bottom Line: Precision Begins with the Right Spindle

Precision isn’t optional—it starts with your spindle system.

As industries move toward all-in-one machining and intelligent manufacturing, GPM’s Motor Spindle + B-axis DD Table isn’t just a mechanical component—it’s a strategic solution that powers the next generation of manufacturing.

Contact GPM today for technical specifications, integration advice, or OEM collaboration.

Whether you’re a CNC machine builder or a high-precision parts manufacturer, GPM is your trusted partner for next-level turn-mill machining.

Updated: 2025/09/01