[Event Recap] GPM × TMBA AI Digital Transformation Showcase for SMEs Successfully Concludes

AI-Powered Digital Transformation: The New Competitive Edge for Manufacturing

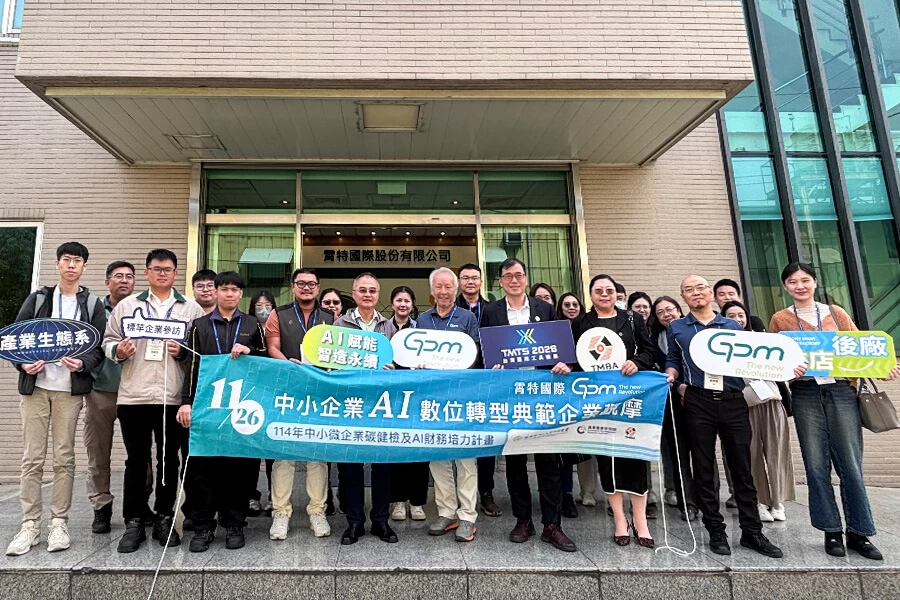

On November 26, the Taiwan Machine Tool & Accessory Builders’ Association (TMBA) and GPM jointly hosted the “AI Digital Transformation Best Practice Showcase for SMEs,” which concluded with great success. Guided by the Small and Medium Enterprise Administration under the Ministry of Economic Affairs, the event gathered representatives from numerous SMEs at GPM’s Taichung plant, where they engaged in presentations, production line tours, and hands-on discussions to explore real-world applications of smart manufacturing.

Why AI Digital Transformation Is Now a Must for SMEs

The global manufacturing industry is undergoing an unprecedented digital shift. AI technologies are no longer optional—they have become essential for manufacturers seeking to enhance efficiency, reduce costs, and strengthen competitiveness.

The core message of this event — “Digital transformation is not a slogan, but a strategic imperative for business sustainability” — invited SME participants to see firsthand how AI can create tangible value on the factory floor and provided actionable insights to accelerate their transformation journey.

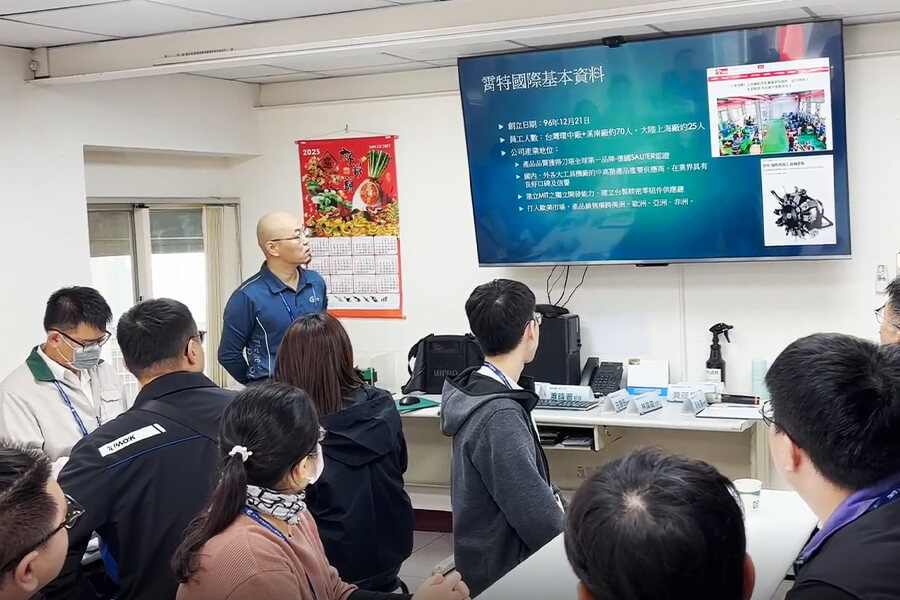

GPM’s Hands-On Experience in Smart Manufacturing

During his keynote session, W.C. Shiau, Project Manager at GPM, pointed out that many critical data flows — from order intake and design, to outsourced manufacturing, incoming inspection, and warehouse operations — still rely heavily on manual work and email communication. This resulted in several operational challenges:

• Data fragmentation and version control issues

Information was stored inconsistently across departments, making it difficult to maintain alignment and prevent errors.

• Lack of production synchronization and delayed feedback

Outdated design versions and late-stage changes often led to rework, schedule delays, and increased costs.

• Serial number management complexity and human entry errors

Multiple manual entries increased risk for mistakes and made traceability more difficult.

• Information gaps in the assembly process

Disconnected reporting, packing, and inspection workflows caused heavy workloads in scanning and shipping.

• Limited data reuse and insufficient analytics for decision-making

Production planning and capacity allocation still relied largely on subjective experience.

To address these challenges, GPM implemented standardized data management, workflow automation, and system connectivity. A complete traceability and feedback mechanism now enables data-driven, agile decision-making — revealing the real impact of digital transformation in manufacturing.

On-Site Highlights: Smart Factory Tour × AI Application Demonstration

Participants explored GPM’s production lines to see how AI supports turret manufacturing, equipment monitoring, and intelligent operations. Real-time dashboards provide actionable insights to prevent abnormalities and ensure high-quality production.

The tour also featured scanning-based AI recognition, enabling automatic material identification, instant data input, and streamlined workflow updates — greatly reducing manual labor and rework waste.

Furthermore, over 70% of GPM’s suppliers now collaborate through a shared digital platform for procurement, delivery confirmation, goods receiving, invoice reconciliation, and labeling — establishing a more efficient, error-free supply chain.

Based on lessons learned from TPS and TQM principles, GPM recommends a phased approach — starting with pilot projects at critical points, then scaling across workflows to ensure low-risk, high-impact transformation.

Impact and Future Outlook

This showcase not only highlighted GPM’s successful AI implementation, but also delivered a replicable transformation model for SMEs.

Highlights:

• Microsoft ecosystem integration demonstration

• Practical AI applications in manufacturing (predictive maintenance, capacity planning, quality control)

• Cross-enterprise exchange platform fostering stronger supply chain collaboration

Looking ahead, GPM will continue to:

• Expand real-time data connectivity

• Enhance automation and intelligent capabilities

• Position AI as a core engine for quality and efficiency — advancing turret manufacturing turret the next era of smart factories

Taiwan Manufacturing: Entering a New Intelligent Era

We appreciate the participation and enthusiasm of every attendee in helping drive this important evolution of Taiwan’s manufacturing sector.

GPM remains committed to working hand-in-hand with the industry to accelerate AI transformation and build a more competitive and resilient manufacturing ecosystem.

Related Videos

Updated: 2025/12/01