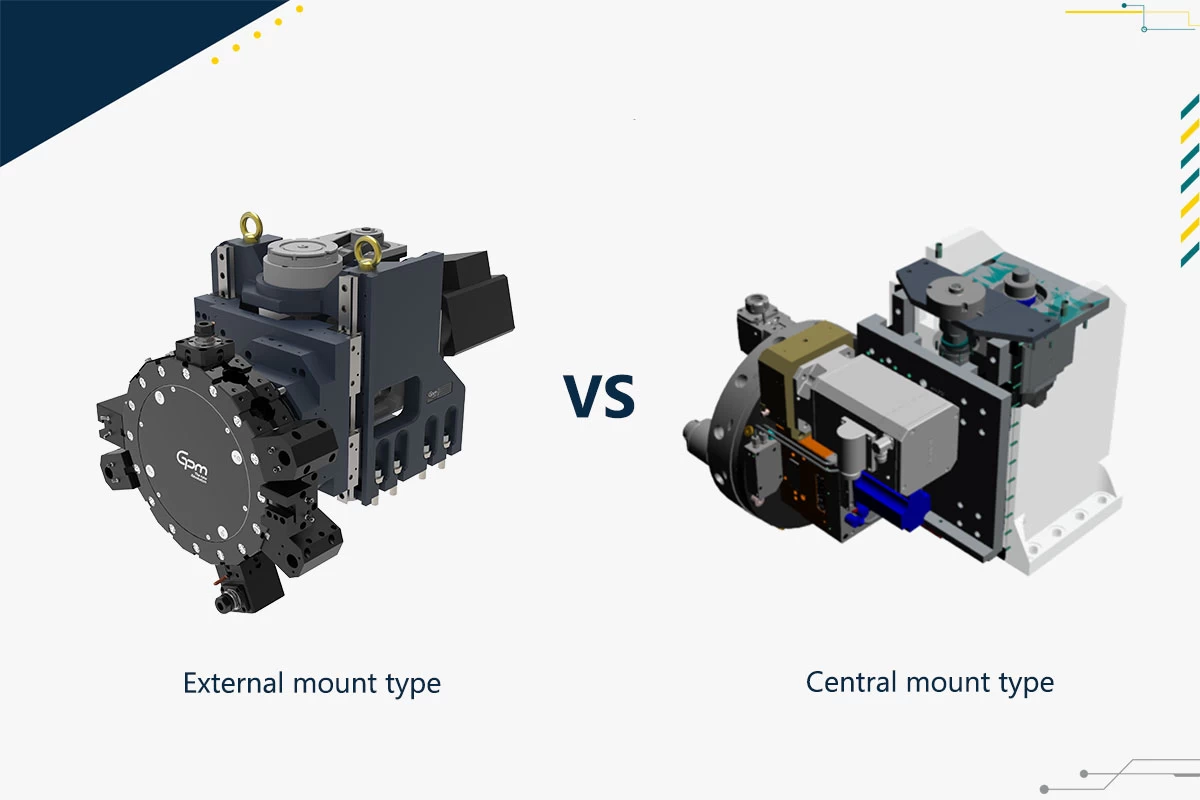

Which type of Y-Axis Turret is more Suitable for You - External mount or Central mount ?

Introduction of Turret with Y-axis

Looking back at the evolution of lathes, from traditional lathes to CNC machines and then SPM (special purpose machines), the machine innovation has been progressing towards much higher quality, convenience, rigidity, flexibility, energy efficiency, and even higher productivity. Today, multi-axis machines have become an essential standard configuration in both production demands and machine tool industry. A machine with only X and Z axes is no longer sufficient; Y-axis is now a must in machine design to suit the current market needs.

Daily necessities, such as smart phones- some phone cases are easier to install while some are not. It tells us that there are tolerance gaps and errors occur during design, production, and assembly processes. The more axes and assembly steps involved, the more cumulative errors there will be, and that makes the precision adjustment more difficult.

GPM upholds a customer-first service spirit, committed to delivering missions and surpassing expectations. With an eye on the future, GPM proactively introduces driven turret with different modes of Y-axis

- High Rigidity:

The integration of the Y-axis structure and the turret enhances precision, improving processing accuracy and stability. - High Rigidity:

The special Y-axis structure boosts the rigidity of the turret itself. - Convenience:

The integration of the Y-axis structure and the turret reduces customers’ design and assembly difficulties, offering friendly disassembly and reassembly. - High Flexibility:

The unique Y-axis turret structure increases the diversity of machining methods. - High Efficiency Processing:

Besides the features of the Y-axis structure, the diversities of turret designs may also enable to achieve automatic tool changes, higher processing speed, and continuous motion processing, making complex multi-processing to be complete in a single setup. - Energy Savings:

Built-in sensors significantly reduce energy consumption, waste, labor, and working hours, improving green energy efficiency.

2 Types of Y-Axis structures:

1. Driven turret with External mount Y-Axis

FEATURES:

- High Rigidity:

The external mount Y-axis type offers powerful rigidity, supporting high-precision and high-stability machining, especially suitable for single/two spindles machines to meet different processing demands. - 2 Roller type linear guideway /Single ball-screw Design:

Utilizing the y-axis structure to provide higher stability and precision. - Y-Axis Travel ±50~60mm:

A stroke range (±50~60mm) allows for more flexible processing demands. - Dual Brake Protection:

The Y-axis comes with an electromagnetic brake system, and an additional optional motor brake system, providing dual protection to prevent unnecessary movement or vibration during processing.

2. Driven turret with Central mount Y-Axis

FEATURES:

- High Rigidity:

Uses 4 roller type linear guideway Y-axis structure to improve the overall precision and stability, ideal for high-precision machining tasks. - Low Interference, and Space Saving:

A compact design with reduced interference, saving 30% of the configuration space compared to traditional designs, improving the overall layout efficiency of the machine. - Large offset design, creating an Extra 80mm Configuration Space:

Offers more configuration space, particularly useful for machining tasks that need to avoid the rear tail, increasing flexibility. - Variety of Tool Disc Options:

Can be equipped with BMT45, BMT55, or BMT65 tool disc, allowing for selection based on different machining needs. - Dual Brake Protection:

In addition to the Y-axis motor's built-in brake function, an additional electromagnetic brake system can be added, providing dual protection to ensure precision and safety. - Suitable for Medium to Light Cutting:

This configuration is suitable for medium to light cutting tasks, ideal for precision machining and low-load workpieces. - Wide Application Range:

Suitable for machines with slant bed configurations and supporting single-spindle single-turret machining methods.

Driven turret with External mount Y-Axis

Driven turret with Central mount Y-Axis

Summary

Both types of Y-axis turrets have their individual advantages. The choice may be based on processing requirements, workpiece characteristics, and the machine structure.

Contact with GPM team for more professional suggestions.

Updated: 2025/09/01