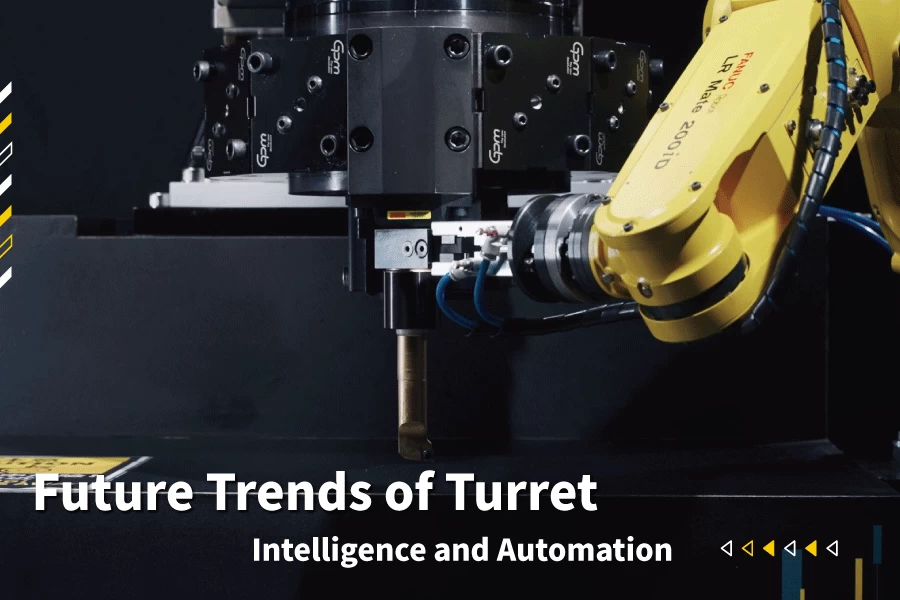

Future Trends of Turret: Intelligence and Automation

2025/09/02

As global manufacturing evolutes towards higher efficiency, automation, and digitalization, CNC machine tools are also undergoing rapid advancement. Being the core element of CNC lathe, turret is evolving from a basic tool indexing mechanism device into an intelligent system—integrating sensing, smart control, and interconnection. Among these evolutions, the widespread adoption of servo turrets and technological improvements are accelerating this transformation. This article helps you explore future trends in turret development and how intelligence and automation are reshaping the machining industry.

1. Traditional Role and Limitations of Turret

The primary function of a turret is to hold and rotate tool holders & tools to support multi-process machining. Traditional hydraulic driven turret offers stable performance but falls short in flexibility and energy efficiency. As manufacturing demands shift toward high-mix /low-volume, high precision, and shorter lead time, hydraulic driven turret is facing difficulties:

-

Slow tool change speed, making it difficult to meet speedy production demands

-

Lack of real-time monitoring, increasing the risk of undetected abnormalities

These challenges are driving the industry to upgrade from hydraulic to servo turrets and move toward smarter systems.

2. Servo Turret: The Foundation of Smart Machining

Servo turret, driven by servo motor, enables precise indexing and clamping through accurate motion control. With advantages like high positioning accuracy, fast response time, and lower power consumption, servo turret serves as the foundation for intelligent machining. Compared to hydraulic turret, servo turret has following advantages :

-

High-speed tool change: Significantly reduce indexing time and increase production output.

-

Real-time monitoring: Status feedback is synchronized with the machine controller, enabling automatic diagnostics and abnormality alerts.

-

Low maintenance: Reduced maintenance costs and lower environmental impact.

Due to these advantages, servo turrets are widely adopted in CNC lathes and multi-tasking machines.

3. Core Features of Intelligent Turrets

Building on servo technology, intelligent turrets incorporate sensors, control logic, and data connection to deliver the following capabilities:

-

Collision Monitoring

By monitoring turret load, vibration, and cutting parameters, the turret can detect potential collisions in real time and trigger preventive alerts—reducing downtime and repair costs.

-

Automatic Compensation and Error Correction

When positioning or repeatability errors are detected, the turret can automatically apply corrective compensation to maintain machining accuracy.

-

Integration with Production Management Systems

Compatible with MES, SCADA, and other Industry 4.0 platforms, intelligent turrets enable visualization of production status and remote monitoring. Tooling data can also be synchronized with ERP systems.

-

Future Prospects : AI Learning and Process Optimization

High-end servo turrets equipped with AI technology can analyze historical machining data to autonomously optimize tool change sequences and machining processes.

4. Enabling Unmanned and Flexible Automation

In a smart factory environment, intelligent turrets play a key role in enabling unmanned machining and flexible automation. Common application scenarios include:

-

Automatic tool selection based on working piece identification.

-

Unattended night shift operation, including autonomous tool condition monitoring and replacement.

-

Integration with robotic systems for continuous loading/unloading and multi-tool processing in a fully automated workflow.

These applications not only reduce labor costs but also significantly improve machining efficiency and equipment utilization.

5. Industry Cases and Benefits

Many advanced manufacturers worldwide have adopted intelligent and servo turret systems to enhance their machining capabilities. Examples include:

-

CNC lathe manufacturers implement servo turrets have enjoyed significant reductions in tool change time, saving hundreds of hours of non-cutting time annually and improving overall production efficiency.

-

Automotive part machining lines in Japan have incorporated intelligent turrets with AI monitoring modules to detect tool anomalies and overloads in real time—reducing scrap rates and maintenance incidents while improving product consistency.

-

Mold manufacturing plants across Europe have deployed turret systems integrated with MES platforms, allowing real-time synchronization of tooling data and dynamic job scheduling—greatly enhancing production flexibility and digital transparency.

6. Future Trends and Challenges

CNC turret systems are expected to evolve in the following directions:

-

Modular and customizable designs to meet diverse industry requirements.

-

Cloud connectivity, enabling remote monitoring and big data analysis.

-

Advanced AI applications, providing predictive maintenance and intelligent decision-making for tool changes.

-

Energy-saving and eco-friendly design, replacing traditional hydraulic systems to support low-carbon manufacturing goals

Conclusion

From traditional hydraulic turrets to servo and intelligent turrets, the evolution of turret technology is profoundly reshaping the machining landscape. Beyond improving accuracy and efficiency, smart turrets are becoming critical driving forces of unmanned production and intelligent manufacturing. As technology matures, future turrets will no longer serve merely as tool indexing devices, but as intelligent hubs with sensing, feedback, and self-learning capabilities.

Companies that invest early in smart turret technology will not only gain a competitive edge but also secure a strong position in the ongoing transformation toward full automation.

Updated: 2025/09/03